|

The very-thin-grain molecular structure provides a very high hardness

without detriment to processability. Its inert behaviour towards

other metals, together with its tendency to self-smoothing make

it ideal for use it is intended for. Actually, going on using it, increasing

hardening can be obtained on the surface while keeping remarkable

antifriction properties. The alloy is forgeable and susceptible to thermal

treatment.

Achieved according to the regulations of the table UNI 4855 "Casting

copper alloys as ingots and castings - Generalities and tests"

VALUES REFERRED TO FORGES PIECES

| Designation |

Composition |

Unitary ultimate tensile

stress

R

[kgf/mm2] |

Elongation

A

[%] |

Brinell hardness

HB

[kgf/mm2] |

Supply |

DURAN 510

DURAN 512

DURAN 514

DURAN Co |

Cu/Al/Fe

Cu/Al/Fe

Cu/Al/Fe

Cu/Al/Fe/Ni/Co |

50÷65

50÷65

50÷70

50÷70 |

10÷20

1÷5

0÷0,5

0÷4 |

120÷150

180÷220

320÷350

320÷380 |

Sand cast

Forged |

The trademarks of bronzes "CM" "DURAN" "MAC"

assure the unchangingness of mechanical and metallurgical characteristics

in the castings we produce.

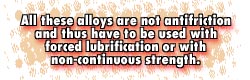

DURAN 510 - DURAN 512

Elicoidal ring gears, scrolls, gibs, wearing plates; matrix pushers

for extrusion; molds for plastic materials; ducting rolls for stainless

steel pipes.

DURAN 514

Owing the remarkable hardness and extreme brittleness it is exclusively

used for the building of stainless steel molds for deep padding; lathe

processing is possible, only, but with very cautiously.

DURAN Co

Very similar to DURAN 514 but with even greater hardness; lower brittleness

and better processability.

|